Wondering what the terms PVD or IP plated mean? Read on to find out what it is all about...

There's a lot of hype concerning exterior coatings on current watches, but just how good are they and are they worth having? As an engineer, I can tell you that the vast amount of these surface coatings are not a new thing, in fact many have been in use for years and years and years. They come into their own in specialist engineering applications where the conditions are extremely predictable; however, use in the watch industry takes them outside of these ideal conditions. Although the coatings are the same, what lies underneath reduces their resilience in certain areas and under certain conditions! These coatings are extremely hard, but their depth is only a few microns, and this is the root cause of the main problem.

Let's take a look at the different types and try to make some sense out of it all.

Citizen ProMaster in "Duratec" on WatchGecko Signature Military Nylon Watch Strap - Credit WatchGecko

Citizen ProMaster in "Duratec" on WatchGecko Signature Military Nylon Watch Strap - Credit WatchGecko

- Regular price

- $60.00 AUD

- Regular price

-

- Sale price

- $60.00 AUD

- Unit price

- per

- Regular price

- $60.00 AUD

- Regular price

-

- Sale price

- $60.00 AUD

- Unit price

- per

- Regular price

- $60.00 AUD

- Regular price

-

- Sale price

- $60.00 AUD

- Unit price

- per

In General Terms

These surface coatings offer a more resilient layer in order to keep your watch looking pristine; they will fend off the everyday scuffs and scratches that would normally inflict light damage to the case, caseback and bezel. They come in various forms, and different coatings suit certain materials better than others. Before we look at a few of the different ones, let's take a look at their strengths and weaknesses. They offer excellent protection against scuffs, light scratches and light knocks, in fact under normal wearing they do their job very well and are worth having. However, they will scratch under certain circumstances and the coating is likely to crack if a substantial impact is encountered. The reason for this is that the underlying case material is quite soft and will deform on impact. The coating however, can't handle the deformation because it's hard and brittle. Once the coating is damaged, either by scratching or cracking it is impossible to repair.

Citizen ProMaster in "Duratec" on ZULUDIVER 1973 British Military Watch Strap: ARMOURED RECON - Credit WatchGecko

Citizen ProMaster in "Duratec" on ZULUDIVER 1973 British Military Watch Strap: ARMOURED RECON - Credit WatchGecko

There is a solution to this, and that involves hardening the substrate first. The word 'substrate' is derived from the Latin 'substratum' and refers to the level underneath or below; all the watch parts that are coated may be thought of as a substrate. Sinn harden their cases/bezels/casebacks, bracelets and clasps before applying the coating; this makes the coating almost damage proof! Damasko is another company that go down this route, albeit in a slightly different way. 316L stainless steel is quite a soft material, but incredibly corrosion resistant; Rolex moved to 904L stainless steel around 1985 and that's even softer, but 904L has other benefits. Titanium is tough but also quite soft; grade 2 titanium is incredibly corrosion resistant in salt water environments but marks fairly easily. Grade 5 titanium is stronger and tougher but is still susceptible to surface marking as well as being less corrosion resistant in certain environments. The object of the exercise in all cases is to keep your watch looking as good as possible, for as long as possible while utilising the most suitable materials for the design of watch.

While PVD and DLC seem to be the 'buzz words' in the watch industry at the moment, there are many, many more surface coatings that perform specific tasks in combatting tribocorrosion, the main area of use. The watch industry is dabbling in the really basic side of coatings at the moment, but things will undoubtedly move on as costs come down.

PVD, CVD, PLCVD and PACVD

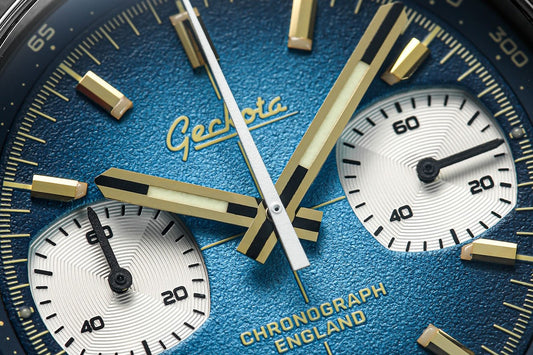

Geckota Phalanx - Credit WatchGecko

Geckota Phalanx - Credit WatchGecko

All these acronyms! PVD stands for Physical Vapour Deposition, CVD stands for Chemical Vapour Deposition, PLCVD stands for Pulsed Laser Chemical Vapour Deposition and PACVD stands for Plasma Assisted Chemical Vapour Deposition. In their basic form they're all much the same thing with the coating being applied by different methods. The main difference between PVD and CVD is that PVD utilises a liquid to produce the coating film and CVD utilises an injected gas to produce the coating film. The variants are just different ways of producing the ideal conditions for the coating to adhere to the substrate involved. Many other aspects are in play here, and the best method for one substrate may not be the best method for another. Look on these as the method of deposition rather than the actual coating. Ion plating is often quoted but this is just another slight variation of PVD.

DLC

Circula DLC ProTrail - Credit Circula

Circula DLC ProTrail - Credit Circula

This is another popular one used in the watch industry. DLC stands for Diamond Like Carbon, and this coating is reputed to be more resilient. The carbon atom is incredibly small and capable of forming an extremely dense, compact film. An additional asset is that it possesses an affinity for electrons; this affinity produces a super-strong atomic bond between the carbon atoms. This, combined with the high density can create an exceptionally hard and resilient coating. However, it's not that straightforward as the carbon atoms can bond in three different ways, these play an extremely important role in producing coatings with different mechanical properties suitable for a wide range of engineering applications. DLC coatings can be applied by the PACVD method along with IBD (Ion Beam Deposition) and SD (Sputter Deposition).

Enough of the Technical!

Hopefully, the above will offer an insight but it's akin to trying to document the history of the universe in 100 words! Now let's take a more practical approach on how to choose. Let's be clear, PVD, CVD and DLC coatings are not scratchproof! They resist the normal day-to-day wear and tear exceptionally well, and if this fits in with your lifestyle, it is undoubtedly the way to go. However, if you lead an active life that includes a lot of outdoor stuff such as diving, snorkelling climbing, caving, mountain biking and the like, it will get marked, there's absolutely no doubt about that! The real downside is that it's likely to look a bit of a mess. Quite a few people look on these battle scars as 'character', but I like to keep my watches looking like new if possible.

Geckota Phalanx - Credit WatchGecko

Geckota Phalanx - Credit WatchGecko

Various companies list their own coating, with Citizen's 'Duratect' being just one; these names are just 'marketing' as such, and offer exactly the same thing. Of course, coatings like these are not new, probably the most famous 'coated' watch was the Seiko 'Golden Tuna' 600m released in 1978, this had a 'one-piece' titanium case that was titanium nitride coated (TiN) producing the gold colour. This is an extremely hard ceramic coating with a face-centred cubic structure applied by the PVD method. This is all very well, but what if you want a watch that will look good all the time? That's simple, you just choose an ordinary case in bronze, stainless steel or titanium and learn to look after it! There are coatings available that are far, far superior, but watch manufacturers won't use them because it is likely to decimate their sales! Of course, cost is also a factor, but someone will make the jump in the near future I'm sure! Sinn and Damasko, as mentioned earlier, are your best options by far as things stand today; they're the nearest thing to an 'unmarkable' watch that you're likely to find!

Do Surface Coatings Need Looking After?

Generally, no they don't. That's the main reason behind their application in the watch industry, to produce a watch with an exterior that needs as little attention as possible to keep it looking good.

Can These Coatings be Applied to Different Finishes?

Yes, they can. These coatings can be applied to brushed, blasted, textured, polished and mirror polished substrates with excellent detail clarity.

Citizen ProMaster in "Duratec" - Credit WatchGecko

Citizen ProMaster in "Duratec" - Credit WatchGecko

The Bottom Line

The choice to go for a coated case is a personal one. This choice is made easier if it's not your only watch, as you can wear it when the conditions allow. I have a Certina DS Action GMT that has a black PVD case, caseback and bezel ring; it looks stunning and I wear it a lot, but I wouldn't go climbing in it! If you're a 'one watch' person, I'd have to say stick with an uncoated case in either brushed, polished, or indeed, a mixture of the two as these are easily refinished; it doesn't matter if the case material is stainless steel, titanium or bronze, it will refinish to 'as new' condition. Avoid blasted finishes as these cannot be replicated at home. If you have a reasonable budget a Sinn or Damasko would be my choice for a watch that will do anything and go anywhere. If you seriously mark either of these it's unlikely that you'll be too bothered, as you'll probably be on your back in a coma, breathing through a tube!

Joking apart, few things are all good or indeed, all bad. It's no use buying a watch that you don't particularly like just because it'll stand up to your lifestyle. Your watch needs to bring joy whenever you look at it, and that must surely be one of the main points! Knowing the watch market as I do, I'd be amazed if your perfect watch didn't exist. You just have to find it. They're out there!